How To for PLM

To locate, view or open files of SmarTeam(ST) CAD Documents through the PLM platform, follow the subsequent steps.

1. Optional prerequisite to enable the opening of STEP files of ST CAD Document directly into SpinFire Ultimate:

Install the software below from CMF. These are available on any CERN Windows machine.

- CERN - PLM Desktop

- Actify SpinFire Ultimate

Note: There is an embedded viewer in the PLM to allow users to view the documents without installing Actify SpinFire Ult., but for a comprehensive review of a document Actify SpinFire Ult. is required.

For the subsequent steps, use either the PLM Desktop app (open the PLM website as shown below), or open the following link in any web browser, https://plm.cern.ch/. However please note, to open a file directly into SpinFire Ult., the PLM desktop must be running. An explicit error will be returned if it is not.

2. Search for the document in the PLM

2.1 It’s recommended to search for a document through the Folders (ST Projects) and Parts (ST Items) it is in, rather than directly, as these queries load much faster and have improved accuracy. Access these search boxes through the table of contents on the PLM Website (or webpage), as shown below.

Note: the Part (Item) reference can easily be deducted from the ST CAD Doc reference: just remove the _ and the 2 last digits

ex: CAD Doc ref :ST1234567_01 -> Part ref: ST1234567

2.2 Query for the desired Folder or Part using the filter fields. Double-click to open the object in its own window.

2.3 Navigate to the document from the Folder or Part window.

The contents of both objects are shown as icons under the main information boxes, click to open them in their own window. Alternatively, navigate using the ARAS grid and different tabs at the bottom of the window as shown in the images below.

2.4 Ensure you open the required revision of the document. A warning will be displayed in the header of the profile card if it is non-latest, with a link to the latest revision.

3. The 3D data of a CAD Document can be viewed from its Profile Card.

- For quick visualisation there is an embedded viewer window on the right-hand side of the window (installation of Actify SpinFire ult. is not required to view this).

- For a more in-depth review, the data can be opened in the local default CAD viewer using the button below (SpinFire Ult. if installed and the PLM desktop is running).

- To download a .stp file of the document, press the arrow in the top box and choose the filetype from the dropdown list.

4. For a drawing, the 2D data can also be viewed on the Profile Card.

- For quick visualisation there is an embedded viewer window on the right-hand side of the window.

- To download a .pdf file of the CAD Document, press the arrow in the top box and choose the filetype from the dropdown list.

- If it is saved in EDMS, there is also a link to this area.

For more information on how to use SpinFire Ultimate please read the following documentation.

FAQ: SpinFire Ultimate

In order to be able to delete an object from the PLM platform (whether it is a Part, a CAD document, a non-CAD document or a Folder), there are a number of requirements that must be met.

All these requirements and the necessary steps are explained in the FAQ below:

The Fast-Track Promotion Workflow can be created from the Part Profile Card.

You can then generate the "Precondition Report" that checks the following pre-requirements:

- Part needs to be in "In Preparation" lifecycle state.

- The initiator of the Workflow needs to have on of the following roles in Design Code set on the Part:

- Equipment Owner

- Senior Integrator

- Configuration Manager

If all them are fulfilled, you can launch the Workflow.

Complete documentation: Fast-Track Promotion Workflow FAQ

The Fast-Track Promotion can be used to approve the Part without going through a Design Verification, in case the Master CAD Documents are in Approved/Released state.

Once the Part is Approved/Released, you may have the need to just attach to the Part additional documentation, without modifying the Master CAD Documents. In such a case, you need to:

- Version the Part.

- Attach the additional documentation needed.

- Promote the Part by using the Fast-Track Promotion, without going through a formal signature process.

Complete documentation: Fast-Track Promotion Workflow FAQ

It is not possible to validate a single CAD Document in the PLM platform.

The Design Verification Workflow acts on the Part and collects all the CAD Documents and Documents attached to the Part, plus its BOM.

Complete documentation: Design Verification Workflow FAQ

The "Replace By" command can be accessed directly from the profile cards of the following object types:

- Parts

- CAD Documents

- Documents

The command is accessible from the "More" menu .

Please note that the name of this command adapts according to the object from which this command is accessed from. Below shows the "Replace CAD" functionality, available from the CAD Document profile card:

This action opens a popup window from which you will be able to search for the object that replaces the "original" one:

As a result:

- The lifecycle state of the "original" object transitions to "Replaced".

- The Profile Card of the "original" object displays information about the object that replaces it, including a direct link to this replacement Profile Card.

For more information, and explanation of the propagation of this tool, please see the following documentation.

There are few basic pre-requirements that must be fulfilled for being able to perform an Assign Drawing(s) Label Workflow.

CAD Documents set as Root Objects must:

- Be of type "Drawing".

- Be in "Approved" or "Released" lifecycle state.

- Have a Design Code assigned through the parent Part.

Additionally, the initiator of the workflow must hold the "Equipment Owner" role in all the Design Codes set on the Root Objects.

Complete documentation: Assign Drawing(s) Label Workflow FAQ

The Assign Drawing(s) Label Workflow can be created from CAD Documents of type Drawing:

Once the Change Item profile card appears, fill in its Description and choose the Drawing Label you need to apply:

You can change the Label of multiple Drawings with the same Change Item.

To do that, you simply need to add the Drawings by accessing the "Root Objects" tab from Workflow profile card, and selecting the highlighted icon:

You can then launch the Workflow by using the following icon from its Profile Card header:

Please note some of the precondition checks below:

- Check that the user launching the workflow is an 'Equipment Owner' in the Design Code set on the Root Object(s).

- Check that all drawings are in Approved state.

Complete documentation: Assign Drawing(s) Label Workflow FAQ

The Assign Drawing(s) Label workflow is used to change the Label of one or multiple Drawings. This workflow only operates on CAD Documents of type “Drawing”.

As soon as the workflow is launched, this triggers the archiving of the Drawing, taking into account the up-to-date Label, and the generation of the viewable file.

Complete documentation: Assign Drawing(s) Label Workflow FAQ

The Preconditions Report can be run by using the button from the Workflow Profile Card.

All preconditions have to be “PASSED” for being able to launch the Workflow.

In case a precondition check is “FAILED”, you will receive a specific error message for this precondition so that you can easily fix the problem.

Complete documentation: Design Verification Workflow FAQ

The Design Verification workflow activates the “Control Activities” on the basis of the Control Rule defined on the Design Code set on the Root Objects and on the Parts composing their BOM (as well as on the attached Documents).

The allowed Control Rules are:

Complete documentation: Design Verification Workflow FAQ

Users holding the Contributor role on the Design Code set on the Root Objects of the Workflow can discard / abandon it when the workflow is still in "Active" state.

This implies that there is at least one control activity that must still be completed.

You can abandon the workflow by using the button → Discard Change Item

Complete documentation: Design Verification Workflow FAQ

You can delegate the Design Verification Workflow activity you have been assign to, to another user holding the role required for its completion (Design Reviewer or Equipment Owner).

To do that, you need to access the "Workflow Activity Completion form" --> Select the "VOTE" button --> Delegate --> choose the new assignee

Then select the "COMPLETE" button to confirm.

Complete documentation: Design Verification Workflow FAQ

Once you access the Profile Card of the Workflow, either using the hyperlink from the notification e-mail, or with My InBasket or via the notification icon on the Dasboard, click on the "VOTE NOW" button (1) available in the "Signs Off" tab, then on "VOTE", and select "Approve" or "Reject" (2).

If you decide to reject, it is mandatory to add a comment.

Then confirm with the "COMPLETE" button (3).

Complete documentation: Design Verification Workflow FAQ

As soon as the workflow is launched, the workflow assignees receive a notification email that contains:

• The reference of the workflow

• The name of the workflow activity the user is asked to vote on

• The direct link to the workflow Profile Card

• The link to the PLM “My InBasket” feature to access the list of all workflow tasks you are responsible for

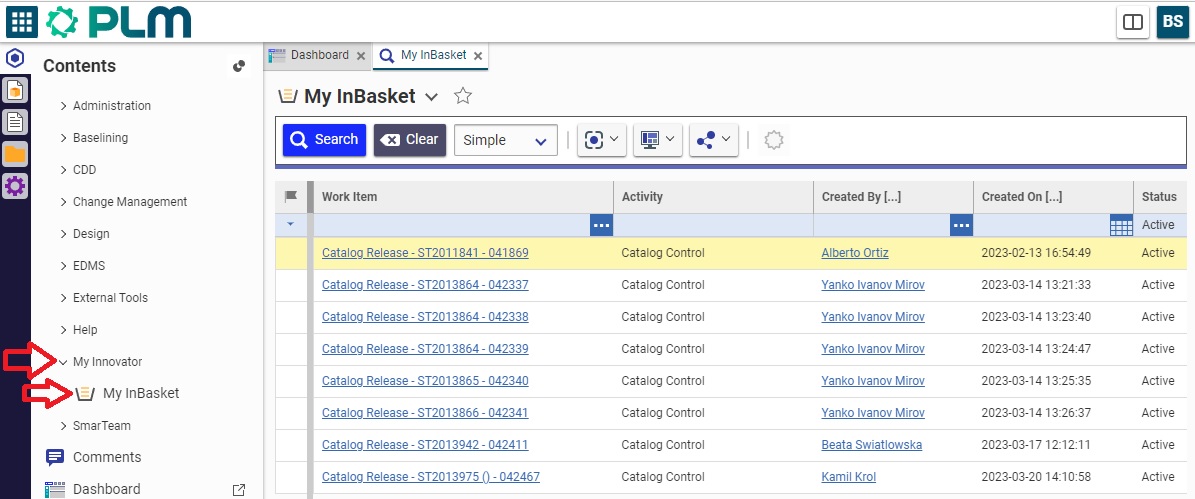

The My InBasket feature is used to access the list of workflow tasks you are responsible for.

You can access this functionality from the Table of Content → Workflows → My InBasket

You can then access a each workflow Profile Card by clicking on the related hyperlink, in the "Work Item" column

Complete documentation: Design Verification Workflow FAQ

The Valid For Integration Workflow is used to freeze an Integration Assembly at a given point in time. This Workflow operates on the Integration CAD Structure only, meaning the Integration Assembly itself and all its CAD Dependencies.

For more information, please follow the document below:

The Valid For Integration Workflow can be created from CAD Documents.

There are few basic pre-requirements that the CAD Document must fulfil:

- The CAD Document needs to be in “In Preparation” lifecycle state.

- A Design Code needs to be assigned to the CAD Document through the Part.

One the Change Item window appears, then the preparation of the Workflow can be finalized by using "Done" button.

After launch the Precondition Checks and if you don't meet any issues during this step, you can launch the Workflow. In case there is a precondition check that "FAILED", a specific error message is included for this precondition to help you correct the problem.

After approving the Workflow, the impacted objects will be Baselined.

To know more details about this specific Workflow, please follow the document below:

You can define the additional reviewers in the "Additional Reviewers" tab of the Part:

Once the Part is collected by a Design Verification workflow, this will automatically assign them a control activity that must be validated to complete the workflow successfully.

Be careful!! In case you add a group as additional reviewer, an additional control activity will be assigned to each member of this group and the workflow will only be completed once every single user will have validated the control activity they have been assigned to.

Complete documentation: Design Verification Workflow

In case the Control Rule defined on the Design Code set on the Root Object is “QAC A”, the “Review by Approval Group” workflow activity is mandatory, and the system automatically suggests you the Approval Group to use. However, you can decide to assign this workflow activity to another Approval Group defined in the PLM.

For selecting/changing the Approval Group, you need to access the “Approval Group” tab from the Design Verification workflow profile card and select the following icon: that appears after you have clicked in the field:

Complete documentation: Design Verification Workflow FAQ

The Release For Integration Workflow can be created from a CAD Document.

There are few basics pre-requirements that the CAD Document must fulfill:

- The target CAD Document needs to be in “In Preparation” lifecycle state.

- A Design Code needs to be assigned to the CAD Document through the Part.

In the Profile Card of a given CAD Document, the workflow can be created by selecting the "Create New Workflow" button.

Then the preparation of the Workflow can be finalized by using the "Done" button.

Then launch the Precondition Checks and if you don't meet any issues during this step, you can launch the Workflow. In case there is a precondition check that "FAILED", a specific error message is included for this precondition to help you correct the problem.

The root object of the Workflow will be set to to the Approved status and the impacted objects will be frozen.

For more information, please follow the document below:

The workflow initiator has to select the people in charge of the “Design Documentation Check” and “Part Design Approval” activities from the “Reviewers” tab, available from the Design Verification workflow profile card.

Design Documentation Check: to be assigned to users holding the “Design Reviewer” role.

Part Design Approval: to be assigned to users holding the “Equipment Owner” role.

For assigning the activity to a Reviewer you need to select the icon that appears after you have clicked in the field:

Complete documentation: Design Verification Workflow FAQ

Root Objects represent the set of data you want to approve.

In case you created the Design Verification workflow from the Part profile card, this Part is automatically added as Root Object of the workflow.

It is possible to add multiple Root Objects to the workflow, so that you can approve different Parts with the same Change Item.

To do that, you simply need to access the "Root Objects" tab from the Design Verification workflow profile card, and select the following icon:

Complete documentation: Design Verification Workflow FAQ

The CDD Control 2 corresponds to the Part Design Approval activity in the new PLM platform.

The assignee of this control activity receives a notification email containing the direct link to the workflow object.

Steps:

- Select the link contained in the email to access the workflow object

- Check the objects affected by the workflow in the Impact Tree

- Click on the Vote Now button to sign off the Control activity through the Activity Completion Form

Complete documentation: Design Verification Workflow FAQ

The CDD Control 1 corresponds to the Design Documentation Check activity in the new PLM platform.

The assignee of this control activity receives a notification email containing the direct link to the workflow object.

Steps:

- Select the link contained in the email to access the workflow object

- Check the objects affected by the workflow in the Impact Tree

- Click on the Vote Now button to sign off the Control activity through the Activity Completion Form

Complete documentation: Design Verification Workflow FAQ

The Release by Integration Workflow is used to validate an Integration Assembly.

This workflow operated on the Integration CAD Structure only, meaning the Integration Assembly itself and all its CAD Dependencies if it has a valid lifecycle state (Approved, Released or Replaced). Once we identify the data we need to validate, we must prepare the workflow object (Change Item) and if all the pre-condition checks are passed, then launch the workflow. This sets the “Approved” lifecycle state on the Integration Assembly and automatically completes without any additional control activity.

For more information, please follow the link below:

If the Batch Import has not yet been launched and the job is still "In Preparation", it can be edited (by clicking on the "Edit" button at the top of the Profile Card). Go to the relationship grid at the bottom of the Profile Card, select the row that corresponds to the document (1) to be deleted and choose the "Delete link Document Batch Import" on the right side (2).

For more information, please check the document below:

If the Batch Import has not yet been launched and the job is still "In Preparation", it can be edited (by clicking on the "Edit" button at the top of the Profile Card). Then the new files can be dragged and dropped into the dedicated area. When the import is ready to launch, close the "Edit" mode and click on the "Launch Import" button.

To find more information, please follow the link below:

Every time a file or a batch of files is dragged and dropped into a Part or a Folder in edit mode, the system automatically created an import job. Each job corresponds to a specific object, i.e. a Batch Import, that is created for that purpose in the PLM Platform. That object has its own Profile Card, properties and lifecycle.

To find the specific Batch Import it is possible by going in the Content and then finding "Design and Documents" and next "Batch Import", then retrieve it by the name, the creation date or the Parent.

When dropping a file into one of the two areas, a table appears.

When importing CAD files, the table contains more fields to be completed. As many fields of the table as possible are prefilled but the proposed default values can be changed and the blank fields filled in.

If you require a new document to be created, leave the 'version a CAD document' column blank. To create a new version of an existing CAD document see the dedicated How-to here.

To enter a value or to change an existing value, double-click in the cell in question. To delete a value select the cell and press the "delete" key on the keyboard or copy a value from one cell to another when you have more files by holding the cell on the corner and moving it to the cell below. The metadata can also be copied and pasted from an excel sheet.

Once the metadata has been entered and the upload is complete, the import can be launched by clicking on the blue "Launch import" button.

The Batch Import can be performed from a Folder or a Part. In both cases, the object must be in edit mode. Once the Folder or the Part is in edit mode, two areas will appear in its Profile Card under “Children” tab.

The files can be dragged and dropped in the desired area.

Dropping files into the area on the left will create or version CAD Documents, which will be linked to the Folder or the Part from where the drag-and-drop operation was launched.

Dropping files into the area on the right will create Documents, which will be linked to the Folder or the Part from where the drag-and-drop operation was launched.

Batch importing involves uploading several files at once to the PLM platform from a File Explorer (Windows, Linux or Mac). To do so, the target folder or part in the PLM must be in edit mode, then the files can be dragged and dropped from the File Explorer into the PLM.

For more information, please follow the link below:

The goal of the Drafts Container functionality is to allow users to approve the Part and its Master CAD Documents without being delayed by the finalisation of the other "secondary" objects that are related to the Part but not relevant for the approval of the Part. On top of that, this functionality allows users to attach "secondary" documentation to the Part at any lifecycle state.

The Drafts Container must be manually activated from the Part Profile Card. You just need to select the icon and choose “Activate Drafts Container”.

Complete description: Drafts Container FAQ.

The Design Collection replaces the EDMS Drawing Folder functionality and serves to support the data exchange process between the Design Office and the Workshop for the production of a given equipment.

Please find more information in this FAQ:

To download CAD files from Parts, Parts attached to Folders, Design Collections or Change Items at once, you need to:

- Access the Profile Card of the object you need to extract the files from

- Select the "Extract files" icon from the Profile Card header

- Choose the BOM Level and what type of CAD files you need

- Select the "Create .zip" button

When executing the "Extract Files" functionality, the selection of the Level applies on the Parts directly linked to the Folder or to the Change Item, or to the Part itself.

The action is now available from the Parts grid in the "More" menu.

This procedure allows the creation and download of a .zip file to your local machine, containing only converted and archived files. CAD native files remain in the PLM.

To print multiple Drawings from your local folder, please read this article.

To print multiple Drawings at once from your local folder in DFS, you need to:

1. Access data in your DFS folder and select all the Drawings you need to print

2. Right-Click and select the option "Open in PDF-XChange Editor"

3. Once PDF-XChange Editor is open, select "File" --> "Print All"

4. Before launching the plotting, make sure that:

- The plotter accepts the format of the Drawings you need to print out

- The highlighted properties are ticked/selected

The Parts are the group of responsible objects for storing all engineering information related to the equipment like 2D, 3D or other documents and files. However, the Part does not contain any files: the files must be attached to the CAD or non-CAD Documents.

In the PLM Platform the Part can be linked to a second Part, but CADs and Documents can be attached only to one Part.

In the Parent Part it is possible to link several Children: Parts (BOM), CAD Documents and Documents.

The Part can be created manually from the PLM Platform or automatically through connector.

Read More: Part

To log-out from PLM Desktop you need to click on the button that represents your account (step 1) and use the "Logout" (2).

Then you need to wait for confirmation window that appears and validate.

Even if the Design Code(s) assigned to the Part(s) involved in the Workflow requires 2 Activities (and thus to define 2 reviewers), sometimes only 1 activity is visible in the Reviewers tab of a Design Verification Workflow under edition, and it is not possible to define the second one.

It is possible that by mistake, a filter has been applied on the "Activity assignments".

To remove it, click on this icon (Clear Search Criteria) and refresh the Workflow

on top of the page.

All activities will now reappear:

CERN account holders can access the PLM with their nice CERN account.

You need to go to the Design Code Profile Card and click on the tab "Team Members". From there you will find Identities (which are group of users) or users with their "Role".

If you want to see the "Role" in the Team, you can search in PLM Desktop for a Part or CAD Document with its Design Code, open it with this Design Code and click on the button to open the Team with all Identities inside and its roles.

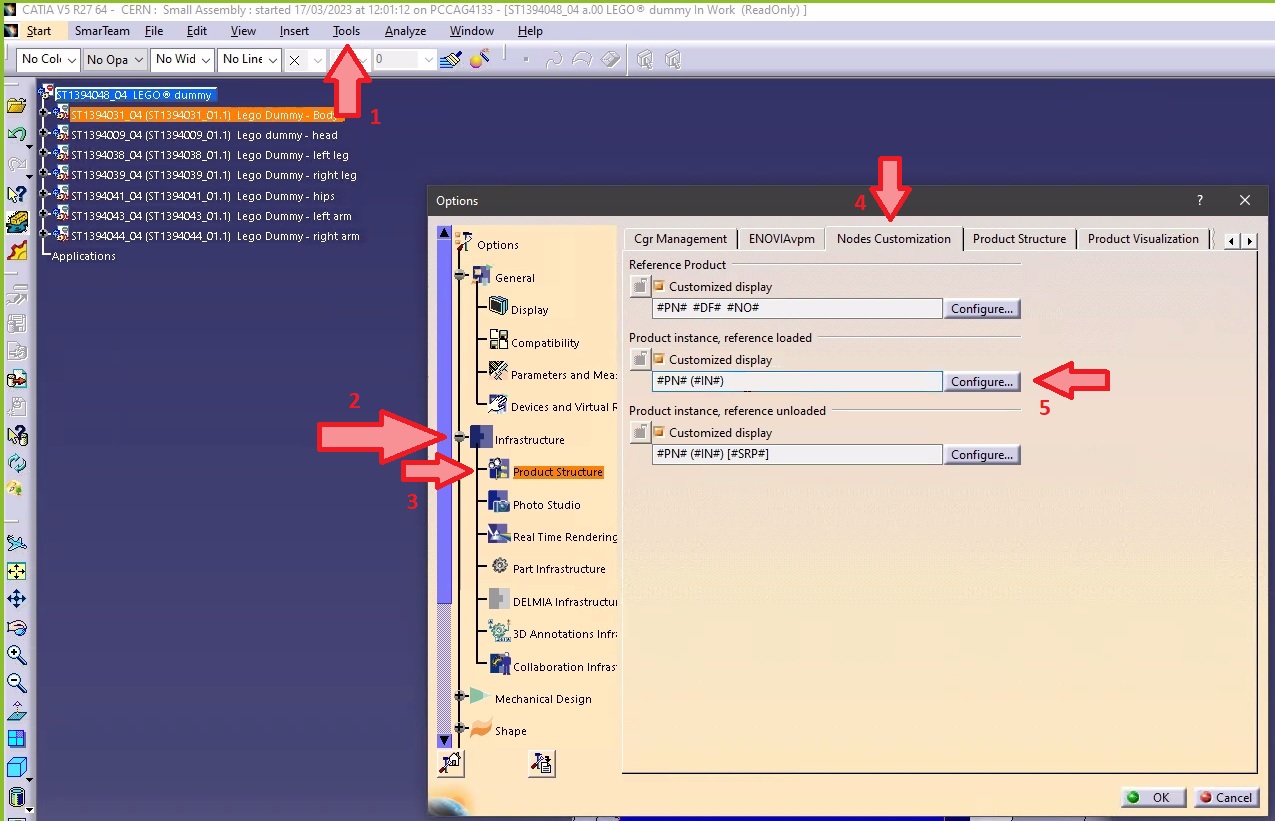

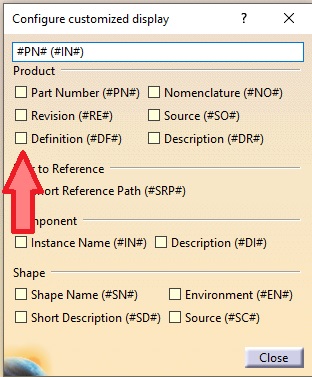

- Go to Tools ➞ Option ➞ Infrastructure ➞ Product Structure ➞ Nodes Customization.

- Tick the "Customized display" (if not already ticked) and open the "Configure customized display" window using the "Configure...".

- In the new window add "Definition" ("#DF") to your product.

- Close. The CAD Definition should be changed in your CATIA tree.

Note 1: if in the same CATIA session, you visualize another product structure from the PLM, the Definition will appear twice.

Note 2: if you want to keep this setting by default for your future CATIA sessions, you need to save your settings.

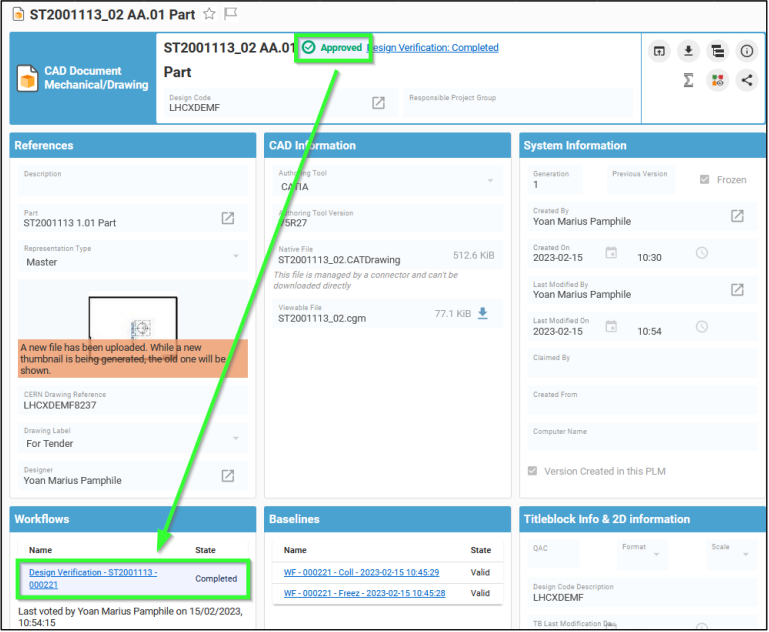

Once the Workflow object (Change Item) has been launched:

As Creator

Go to Part/CAD Document from which the Workflow has been launched, then go to the "Workflow" section of the Part/CAD Document Profile Card and click on the link of the corresponding Workflow.

As reviewer

Go to "My Innovator" in the Table of Content, when in "My InBasket". The sought Workflow will be displayed in the table.

As reviewer, you can access to the profile Card of the Workflow, either using the hyperlink from the notification e-mail, or through the My InBasket page or via the notification icon on the Dashboard.

From the workflow profile card, all the drawing affected by the workflow that need to be reviewed are displayed on the tab 'Affected drawing'.

Click on one of the drawings to open it in its own tab. To view the drawing either open it through the integrated viewer, of download the .pdf.

There are few basic pre-requirements that must be fulfilled for being able to create a Design Verification Workflow:

- The Part must be in "In Preparation" lifecycle state.

- A Design Code must be assigned to the Part.

- The creator of the Workflow must hold the Contributor role in the Design Code set on the Part

You can create and launch a Design Verification by following the information contained in this article.

Complete documentation: Design Verification Workflow FAQ

Once the workflow is launched, the creator of the workflow can, in case of need, reassign the workflow activities (that are not yet completed) to another user. This one must have the role required by the activity (Design Reviewer or Equipment Owner) on all the Design Codes set on the objects collected by the workflow.

For reassigning a given workflow activity you need to access the Reviewers tab of the Change Item ➞ Right-click on the activity ➞ Reassign.

Complete documentation: Design Verification Workflow FAQ

You can create the Design Verification Workflow from the Part by clicking on the icon of the Workflow and then select Design Verification in the drop-down menu. Any already existing Design Verification workflows of the Part that are "In Preparation" will be proposed. Alternatively a new one can be created.

Once the Change Item profile card appears, select the Behaviour of the Workflow, fill in its Description and choose the Drawing Label.

Choose the Reviewer(s) who will perform the control(s), click on Done.

Launch the Precondition tests:

Then launch the Workflow:

The reviewers will receive a notification e-mail to invite them to perform the control.

Complete documentation: Design Verification Workflow FAQ

The Design Verification workflow is used to approve the Design data. Since we are working in Part Centric mode, this workflow allows to approve the Part and all its content. In other words, it will not be possible to approve a single Drawing by using this workflow.

If you want to know more details about designing the Workflow, please follow the document below.

Complete documentation: Design Verification Workflow FAQ

The baseline’s behaviour is determined by the expansion strategy and the filter it uses. The filter corresponds to the type of documents that are assigned (or not) to the baseline.

The only expansion strategy used is the top-down strategy. You can use the filter to assign a baseline to a part, a CAD document or a non-CAD document, provided that the status of the object from which it is generated is “In Preparation”. As stated in the “Baseline propagation” section, the baseline will not propagate to objects that have “Released” status. These objects are already frozen.

After a baseline has been created, the document(s) assigned to it cannot be edited or deleted (lifecycle status cannot be modified). The information about the baseline can be found in the document’s profile card.

The structure covered by the baseline cannot be edited and is frozen. The only way to modify documents is to create a new version of the document in question. Only the version used to generate the baseline is frozen. If a part has several versions, they are not all affected by the baseline.

To more details about this, please follow the document below (page 14).